In heavy-duty logistics and commercial transportation, driver safety technology has moved from “optional” to operationally essential. But for fleet managers, OEMs, and system integrators, the real problem isn’t simply choosing a Driver Fatigue Monitoring System manufacturer—it’s choosing one whose product can survive long-haul reality and deliver consistent detection performance over time.

AI algorithms get most of the attention. In practice, hardware engineering determines whether the system stays reliable across temperature swings, vibration, electrical noise, and years of daily use. This article breaks down the key hardware fundamentals behind a professional Driver Drowsiness & Attention Warning System (DDAW) for trucks, using AUTOEQUIPS Activue DDAW as a reference point.

From Basic Sensors to AI Vision: Why the Hardware Baseline Changed

Legacy systems: simple triggers, constant false alarms

Early driver monitoring often relied on basic sensors or simple camera triggers. These systems struggled to distinguish actual fatigue or distraction from normal driving behavior, leading to false alarms—like triggering when a driver checks mirrors or glances at the instrument cluster. The result is predictable: driver frustration, reduced trust, and eventually device disablement.

Modern DDAW: real-time AI requires real compute

Today’s standard is AI-based distraction warning for trucks, where computer vision models analyze facial landmarks and behavioral patterns. But to run those models continuously, the platform needs:

- Stable processing performance (no lag or frame drops)

- Consistent image input quality (sharp, usable frames)

- Reliable power and signal integrity (no resets, no noisy data)

- Physical endurance for the commercial environment

In other words, software capability is capped by hardware reality.

Why professional DDAW isn’t the same as a consumer dashcam

A common misconception is that an AI dashcam and a commercial-grade DDAW are basically the same product with different branding. The real difference shows up in two places:

- On-device AI compute capacity (for continuous inference)

- Input stability and clarity (so the AI isn’t “guessing” from low-quality frames)

The role of advanced deep learning on the edge

High-end commercial systems use advanced deep learning algorithms to map facial features precisely. That precision is how you reduce false alarms and increase confidence in detection outcomes. But the AI model’s accuracy depends heavily on:

- Frame clarity (resolution + lens consistency)

- Exposure stability (avoiding fluctuating image conditions)

- Real-time throughput (so alerts are timely, not delayed)

This is why hardware specs are not “nice-to-have”—they directly affect alert quality, driver acceptance, and long-term uptime.

Built for Harsh Operations: Industrial-Grade Hardware Specifications

Commercial vehicles operate in environments that quickly expose weak designs—extreme temperatures, electrical spikes, constant vibration, and continuous daily runtime. Below are practical specs that matter for heavy-duty deployment.

Thermal Stability: -20°C to +70°C operating range

A DDAW device must maintain performance through winter cold starts and summer cabin heat. AUTOEQUIPS designs components tested for -20°C to +70°C, supporting stable operation across common heavy-duty fleet climates.

Why it matters operationally:

- Prevents heat-related throttling, lag, or unexpected shutdowns

- Avoids cold-start instability that causes early-shift failures

- Improves reliability for multi-region fleets

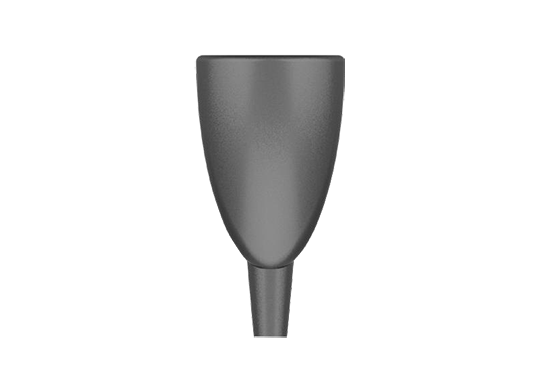

All-Glass Optical Lenses (4G): Stable clarity over time

In real-world fleets, optical degradation is a silent failure mode. Plastic lenses can warp, haze, or yellow over time—especially under repeated temperature cycling. A 4G all-glass optical lens helps maintain long-term clarity and focus stability.

Why it matters to AI detection:

- The AI depends on clear facial detail for accurate analysis

- Stable focus reduces model uncertainty and false alarms

- Consistent image input supports reliable long-term performance (not just “day one” demos)

Voltage Protection for Truck Power Systems: 12V/24V with wide input tolerance

Trucks are prone to voltage transients, especially around ignition. AUTOEQUIPS supports 12V/24V systems and a wide input range compatible with 9–36V environments, helping protect electronics from surges that can damage consumer-grade devices.

Why it matters:

- Reduces random reboots and data loss

- Protects sensitive components during crank and ignition events

- Supports mixed vehicle platforms (12V light commercial + 24V heavy-duty) with one solution

Integration Readiness: DDAW as Part of Fleet Safety Operations

For fleets and integrators, the goal isn’t just “an alert in the cab.” The goal is usable events, tied to operational context, that can improve coaching, safety KPIs, and compliance workflows.

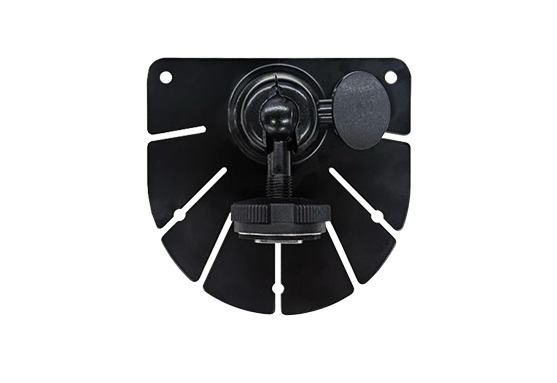

Compact in-cabin footprint

Truck cabs have limited mounting real estate. A compact device footprint helps installations remain unobtrusive and reduces interference with driver visibility and cabin ergonomics. AUTOEQUIPS uses a 115mm × 33mm form factor designed for practical in-cabin mounting.

Connectivity that supports system-level value (I/O + CAN)

Modern fleets want systems that integrate with telematics and vehicle signals. With I/O ports and CAN bus integration, a DDAW device can work as a connected node rather than a standalone camera.

Example operational benefits (when integrated):

- Safety events can be associated with vehicle context (e.g., speed, brake status)

- Events can be transmitted to a fleet center for review and coaching workflows

- Integrators can design broader solutions using the same interface standards across fleets

When paired with 1080P video events, integration enables richer incident interpretation and faster operational response.

How to Evaluate a Driver Fatigue Monitoring System Manufacturer

Many products look similar from the outside. The real differentiation is whether the manufacturer can control and support the system end-to-end.

Key questions for fleet buyers, OEMs, and distributors

When you evaluate a Driver Fatigue Monitoring System manufacturer, look for signs of true engineering ownership:

- Do they control both hardware design and algorithm capability, or are they reselling a generic platform?

- Can the device sustain real-world operation (temperature, voltage, long runtime), not just lab tests?

- Do they provide integration options (CAN/I/O) that align with your telematics stack?

- Can the platform evolve as requirements change (vehicles, regions, operating conditions)?

For heavy-duty fleets, durability and integration readiness are not “extras”—they determine whether the program scales.

Conclusion: Hardware Is the Foundation of Reliable DDAW

In a market crowded with white-label devices, hardware quality is the difference between a system that looks good in a proposal and one that performs every day on the road. Professional DDAW isn’t just “AI + camera.” It’s AI running on stable compute, fed by consistent optics, protected by robust power design, and deployable at scale through integration.

If you’re selecting a DDAW solution for heavy-duty fleets, prioritize manufacturers that can deliver both: industrial-grade engineering + real-time AI capability, designed for commercial transportation conditions.